快速鏈接

系統(tǒng)概述

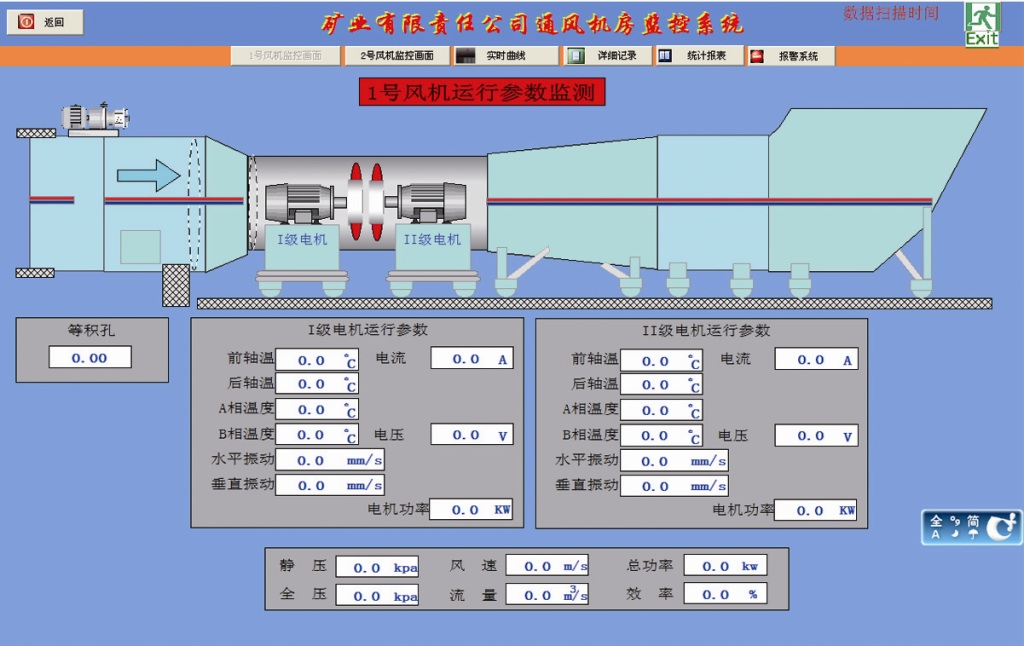

由于礦山作業(yè)對通風(fēng)的特殊要求,通風(fēng)系統(tǒng)、設(shè)施的可靠性承擔(dān)著巨大的責(zé)任,一個良好的通風(fēng)系統(tǒng)就是一個礦的巨大財富。礦用主通風(fēng)機在線監(jiān)控與故障診斷系統(tǒng)主要是針對金屬礦山主通風(fēng)機研發(fā)。該系統(tǒng)符合最新版《金屬非金屬地下礦山監(jiān)測監(jiān)控系統(tǒng)建設(shè)規(guī)范》,參考標準MT 421-1996《煤礦用主要通風(fēng)機現(xiàn)場性能參數(shù)測定方法》、 GB/T 10178-2006《工業(yè)通風(fēng)機現(xiàn)場性能試驗》為依據(jù),應(yīng)用工業(yè)計算機監(jiān)測技術(shù)對礦用大型通風(fēng)機的運行狀態(tài)進行連續(xù)在線測量與處理,以多種方式提供通風(fēng)機運行狀態(tài)的各種數(shù)據(jù),保障通風(fēng)機的安全運行和方便風(fēng)機的性能測試。

本系統(tǒng)采用國際先進的研華工業(yè)控制計算機及西門子300系列PLC,防塵、抗震、抗干擾能力強,性能穩(wěn)定,功能強大,擴展方便;測量傳感器、變送器均選用國際國內(nèi)名牌產(chǎn)品,誤差小于0.5%;輸入通道板的分辨率為1/27648,系統(tǒng)采用一系列抗干擾措施,保證測量誤差小于2%。

System overview

Due to the special requirements of mine operation for ventilation, the reliability of ventilation system and facilities bears great responsibility, and a good ventilation system is a great wealth of a mine. The online monitoring and fault diagnosis system of mine main ventilator is mainly developed for metal mine main ventilator. The system conforms to the latest edition of the "Metal and Non-metal underground mine monitoring and monitoring system construction Code", referring to the standards MT 421-1996 "Main fan field performance parameter determination Method for coal mine", GB/T 10178-2006 "Industrial fan field performance test" as the basis. The industrial computer monitoring technology is applied to continuously measure and process the running state of the large fan used in mining, and various data of the running state of the fan are provided in various ways to ensure the safe operation of the fan and facilitate the performance test of the fan.

This system uses the international advanced Advantech industrial control computer and Siemens 300 series PLC, dustproof, seismic, anti-interference ability is strong, stable performance, powerful function, easy to expand; Measuring sensors, transmitters are selected international and domestic famous brand products, error is less than 0.5%; The resolution of the input channel plate is 1/27648, and the system adopts a series of anti-interference measures to ensure that the measurement error is less than 2%.

系統(tǒng)功能特點

系統(tǒng)具有在線幫助、狀態(tài)監(jiān)控、故障報警、信息查詢與打印、數(shù)據(jù)遠程傳輸、遠程控制六大功能。

1)監(jiān)測電機電量參數(shù):三相電壓和線電壓、三相電流,有功功率、無功功率、視在功率、功率因數(shù),頻率等電量;

2)監(jiān)測電機定子每相繞組溫度,軸承兩端溫度(電機自帶溫度傳感器);3)監(jiān)測風(fēng)機的水平和垂直振動;

3)監(jiān)測風(fēng)機靜壓、全壓、靜壓效率、全壓效率、風(fēng)速、流量;5)監(jiān)測一氧化碳濃度;

4)監(jiān)測風(fēng)機開停信號、正反風(fēng)信號,變頻器運行狀態(tài);

5)控制主通風(fēng)機正常狀態(tài)下的開、停,控制礦井需返風(fēng)時的倒轉(zhuǎn)反風(fēng);

6)遠程手動/自動轉(zhuǎn)速調(diào)節(jié)(變頻電控):在監(jiān)控界面手動輸入頻率,或由壓力傳感器信號反饋回來,系統(tǒng)根據(jù)該信號進行自動反饋調(diào)節(jié)變頻頻率來改變風(fēng)機轉(zhuǎn)速,兩種方式由操作員選擇;

7)自動記錄通風(fēng)機運行時的監(jiān)測參數(shù)值,并自動生成表格,有關(guān)信號的圖譜、曲線圖以及數(shù)據(jù)顯示直觀簡明;提供歷史數(shù)據(jù)的查詢;

8)顯示系統(tǒng)的實時報警信息,并提供歷史報警信息的查詢;

9)主通風(fēng)機監(jiān)控系統(tǒng)具有工業(yè)以太網(wǎng)接口、PROFIBUS DP總線接口、CAN現(xiàn)場工業(yè)總線接口、RS485總線接口,可接入其他監(jiān)控設(shè)備和傳感器。可接入單位監(jiān)控系統(tǒng)網(wǎng)絡(luò)平臺,實現(xiàn)監(jiān)控數(shù)據(jù)網(wǎng)絡(luò)共享,經(jīng)授權(quán)的網(wǎng)絡(luò)終端用戶隨時監(jiān)測通風(fēng)機的狀態(tài)、運行數(shù)據(jù)、故障情況,具有系統(tǒng)和節(jié)點自診斷功能,并可對通風(fēng)機遠程操作和管理;

10)遠程監(jiān)控站在線幫助功能,在接到用戶請求幫助的消息后,彈出一個關(guān)于相關(guān)主題的幫助窗口,將用戶所需的幫助信息顯示出來。操作人員可隨時查詢幫助文件,解決操作中遇到的疑難問題。

System function characteristics

The system has six functions: online help, status monitoring, fault alarm, information query and printing, remote data transmission and remote control.

1) Monitoring motor power parameters: three-phase voltage and line voltage, three-phase current, active power, reactive power, apparent power, power factor, frequency and other power;

2) Monitor the winding temperature of each phase of the motor stator and the temperature of both ends of the bearing (the motor comes with a temperature sensor); 3) Monitor the horizontal and vertical vibration of the fan;

3) Monitor the static pressure, total pressure, static pressure efficiency, total pressure efficiency, wind speed, flow rate of the fan; 5) Monitoring carbon monoxide concentration;

4) Monitor the fan start and stop signal, positive and negative wind signal, inverter operation status;

5) Control the opening and stopping of the main ventilator under normal conditions, and control the reverse reverse air when the mine needs to return air;

6) Remote manual/automatic speed adjustment (frequency conversion electronic control): manually input the frequency in the monitoring interface, or the pressure sensor signal feedback back, the system according to the signal automatic feedback to adjust the frequency conversion to change the fan speed, the two ways are selected by the operator;

7) Automatically record the monitoring parameter values of the fan during operation, and automatically generate a table, and the graph, curve and data display of the relevant signals are intuitive and concise; Provide historical data query;

8) Display real-time alarm information of the system, and provide historical alarm information query;

9) The main fan monitoring system has industrial Ethernet interface, PROFIBUS DP bus interface, CAN field industrial bus interface, RS485 bus interface, and can access other monitoring equipment and sensors. Can access the unit monitoring system network platform, to achieve monitoring data network sharing, authorized network end users at any time to monitor the status of the fan, operating data, fault situation, with the system and node self-diagnosis function, and can remotely operate and manage the fan;

10) Remote monitoring station online help function, after receiving the user's request for help message, pop up a help window on related topics, the user needs to show the help information. Operators can query help files at any time to solve difficult problems encountered in the operation.